Let's summarize at the beginning; We can choose between Optical, Astronomical and Hybrid drivers. Optical has the best value for money, although some people don't like it for being too "diligent". Astronomical is quite expensive and unfortunately tracks the sun instead of the radiation. REI HYBRID Solar Tracker is the most accurate and efficient but not so much that its price is reasonable. In addition, both Astronomical and Hybrid requires the magnetometer to be calibrated after each power failure - disaster.

Astro / Optic difference: 200 USD

Hybrid / Optic Difference: 300 USD

Solar Tracker without a properly selected driver is just a construction. A good driver is needed to achieve efficiency goal. At the testing or research stage, many important aspects that affect the way the entire set works or its safety can be omitted. By testing various solutions over the years, we managed to break many elements and even knock over the entire tracker. We will try to share our experiences with you.

Time to disrupt the artificial division of drivers for those operating in closed and open systems. This division results from assigning certain precursors of particular solutions to the technology, what further causes stagnation in driver development. In the current market there are only a few of products which bring satisfactory results in tests. All of the remaining solutions focus mainly on theoretical issues and not on constructive aspect for the market needs.

By using developed nomenclature, closed systems will work fine in tropical regions with insignificant occurrence of cloudiness – only in places where rainy seasons or any other climatic changes in the environment between seasons are minimal. Open loop systems, in the form of pure algorithm, will be able to solve problems of unstable irradiation, however, their usefulness is rather laboratorial.

The REI vision assumes a conception of a driver which exceeds the current level of technology, a driver which successfully realizes a concept of hybrid system and at the same time is fully configurable and manageable. A driver which leaves the choice for a user. We abolish restrictions produced by a conventional division resulting from inflexibly coded operational logic.

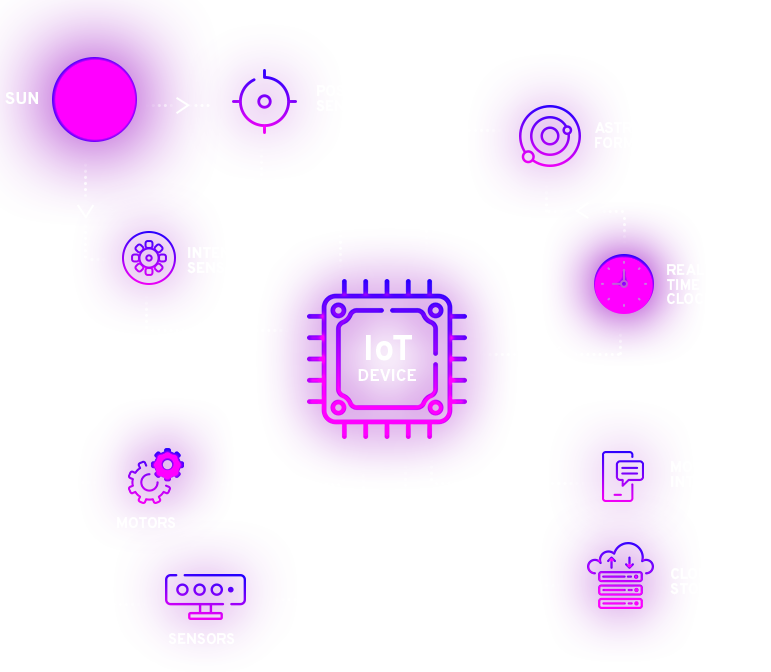

REI Driver opens unlimited possibilities, thanks to the usage of efficient IoT platforms, which allow to relatively easily, change implementation of primary and secondary algorithms, therefore to control the behavior of the whole system.

By supplementing algorithm calculations with transformations of data ongoing from sensors and unlimited number of peripherals, it is possible to run auto-calibration of the system even in the most harsh field conditions.

We open the way to facilitate collection of data for further research. We enable a mutual correction of operation of cooperating racks in a master-slave configuration. Therefore, we create an opportunity to use machine learning or artificial intelligence for more sophisticated applications

It's good to know what my options are, but most of all to have a choice. If I decide to build a solar tracker for my own needs. Do I have to invest in a great solution that requires internet access, a data collection server, artificial intelligence and many other elements. Of course not. Let's think about what we will need for the tracker to do "the job" and his "mistakes" and awkwardness will not cause us significant loss in tracker performance.

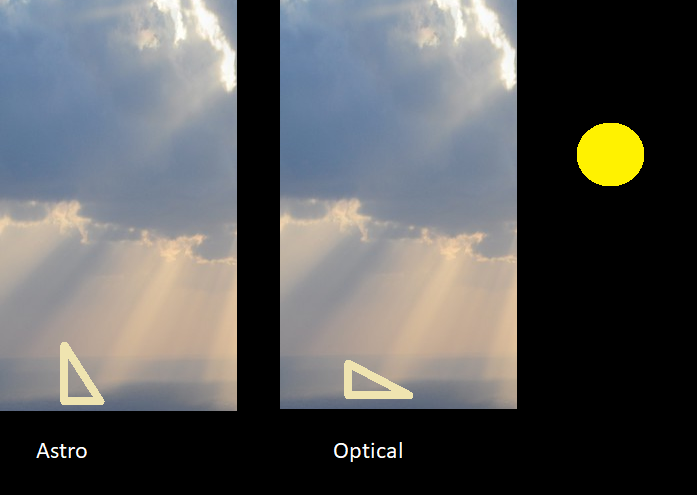

Exactly: The division of trackers into astronomical and optical was not brought up by accident. The one mentioned earlier (open / closed system) is, so to speak; "Off the topic." As a recent tracker owner, I will focus on its accuracy. This means that none of the listed ones will meet my expectations. ... what is the accuracy, after all, tracking is about performance, not accuracy. I will explain this using the example of disadvantages. From a performance perspective - not a sun position, but the direction of the radiation does matter. (look at this photo)

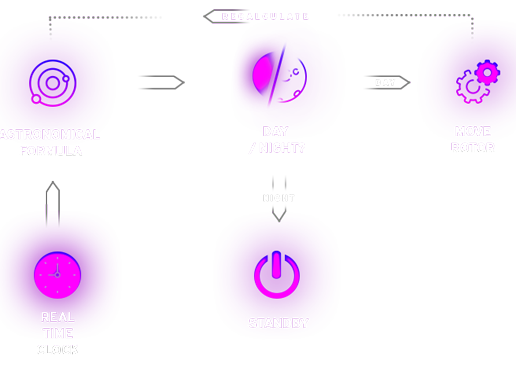

The Astronomical Controller - Ad.1 works well only in perfect weather, the position of the sun is consistent with the angle of incidence of the light radiation. It works very badly if we are partially cloudy (thin layer of high clouds). While the azimuth is quite often consistent with the direction of the light, then the elevation of the sun has nothing to do with the angle at which the light falls on cloudy days. When this happens - early spring, 1/2 summer, autumn. So the astronomical driver in our climate, will work well only for 1/2 of the year and single days of spring, the other days of the year it looks towards the sun - not where it needs to be. As for point 2, we tested many magnetometers and inclinometers that play a very important role for the controller - without them, the controller does not know how actually the tracker is set. It turns out that it's either expensive or not accurate at all. Devices need to be properly calibrated and still "afraid" of any changes in the magnetic field. Power lines, steel structures, warehouses, a magnet in a pocket will cause the so-called "ironing" or de-calibration of the device - the sun positioning will be incorrect. The controller will set the structure with slight inaccurracy even on those long-awaited sunny days with clear skies, the tracker will not be as effective as it should be.

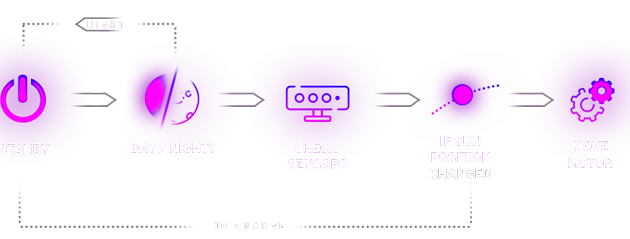

Optical Control - Ad.1 Only works well when the weather is stable. What I mean? the point is that the direction of the light changes depending on cloud density. When we have days with high volatility, e.g. every hour the clouds change their thickness, the driver has to work hard. Sometimes he even rushes to that position that it was unable to find the direction of the light. This happens around 1/3 spring and 1/3 autumn. The solution to the problem is adding parameters (light force, displacement times) so as to reduce the sensitivity to variability. However, this in most cases forces us to use limiter switches (mainly E - W) so that the tracker would not be able to twist so much that the light fell directly on his back.

Summarizing; both solutions have disadvantages. We checked the impact of these disadvantages on the efficiency of the installation for 3 years. It turns out that the simplicity and low purchase costs of optical driver do not detract its quality of work. The installation working under its control is 5-7% more efficient per year than an installation based on an astronomical driver, even with an expensive magnetometer and inclinometer.

REI HYBRID Solar Tracker. Solution with light sensors, implemented astronomical algorithm, magnetometer and limiters (ampere and physical) is by far the best. We produce such solutions with dedication to the most demanding. Compared to Astronomical controller, we obtain 10% more energy per year, compared to the optical one, about 3-4% Is that a lot? To explore this, a new article must be written. The REI HYBRID controller costs approx. USD550. (in the basic version)

Difference: 200 USD

The wind force sensor is a very necessary element - do not leave the tracker turned on without it. The day will certainly come when the tracker will become a wind collector like a sail. BUT ATTENTION - without exaggeration you do not need an accurate anemometer, only a sensor that will generate an impulse to the controller at a given wind force. Very often I see professional devices that unnecessarily increase costs. After all, this is only an indicator that is supposed to act as a threshold and not serve as a weather station.

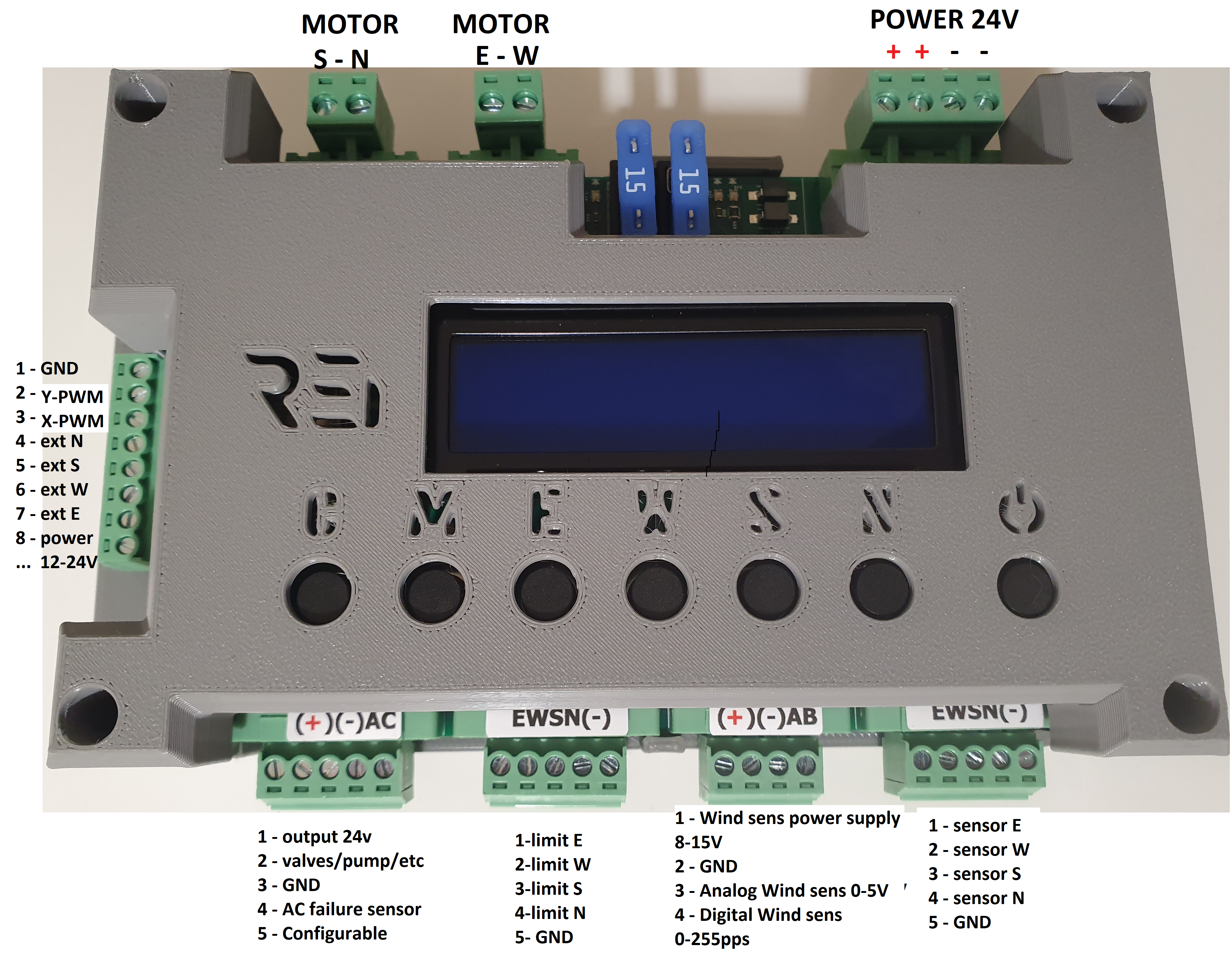

Because it's always about cost, and believe it or not, housings often cost more than electronics alone (if you don't take software into account). All drivers look the same and have the same pinout. Differences are inside. Mostly the type of processors used. They have additional modules (PCBs, power supply, passive components, peripherals). We have not been able to keep the same derivation for 240V AC motors. AC 240V has higher voltages and we had to take care of insulation. Nevertheless, the housings themselves will always be the same, so one day we will order a mold for an injection molding machine and especially for you and for the "cause" we will lower the production costs. *** If you want your driver to look different than one or another using such 3D printed - for a fee, we can design and print everything for you.

The upper side of the controller has a fuse and terminals for sensors, wind and light. The light sensor is made of small photovoltaic cells and not diodes / photoresistors. Photoresistors are sensitive to different wavelengths of light than a photovoltaic panel, therefore, although the diode is cheaper, photovoltaic cells provide better results. Connection according to the colors.

The wind force sensor is a simple DC element that generates a voltage appropriate to the wind force, thanks to which the controller will perform the adjustment procedure in the event of appropriate signal. Green connection is "- minus", red is "Signal" *** Other linear anemometers can be used. Configuration allows you to change the procedure activation threshold.

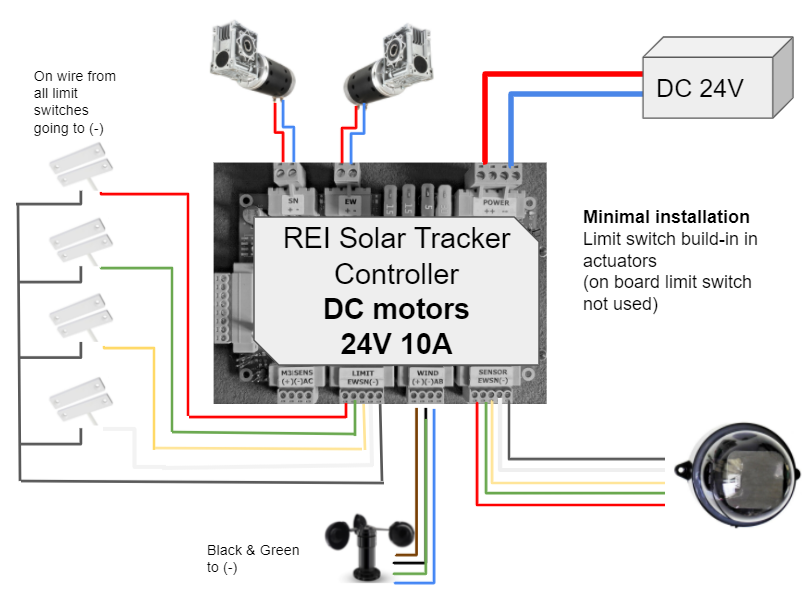

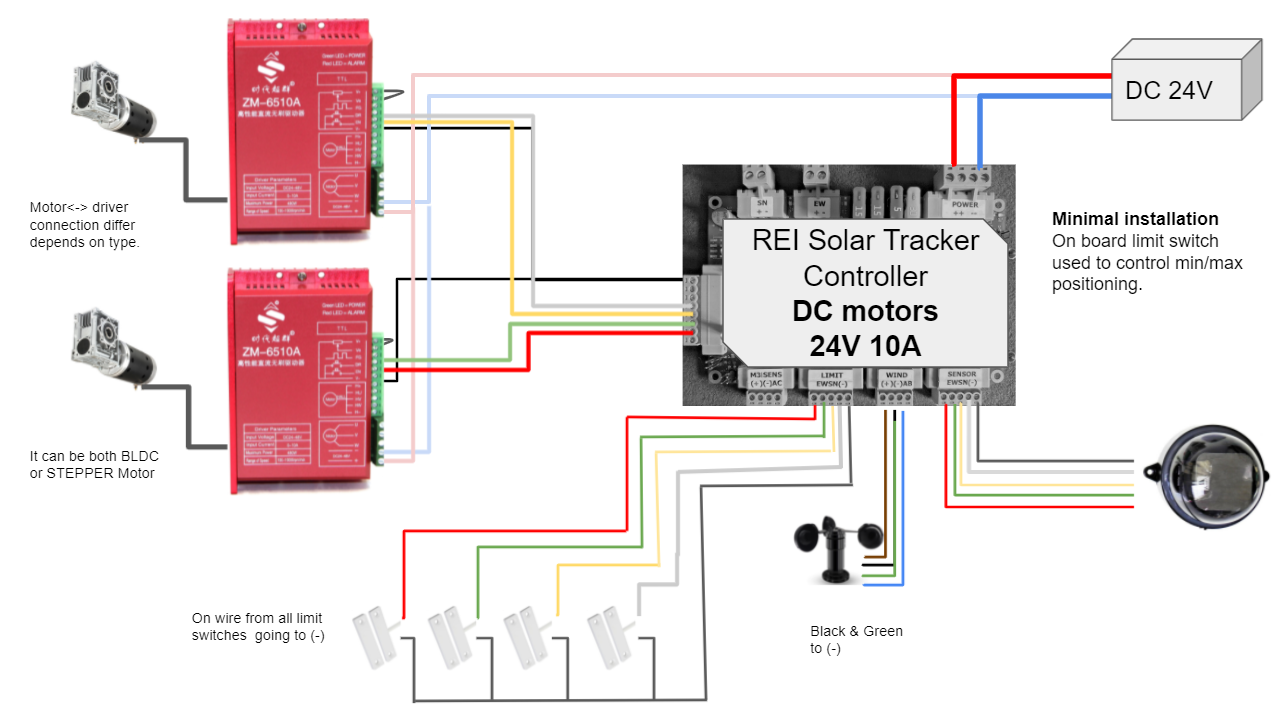

The lower side of the controller has terminals for power supply, outputs for DC motors, and outputs for movement limiters (limit). We connect a DC power supply not smaller than 15A to the power supply. We connect motors not larger than 140W to the motor outputs. As limiters, we use the cheapest two-wire "NO" magnetic reed switches (eg from the alarm system). So that one wire from all reed switches is connected to "COM", while the other wire of individual reed switches is connected to individual outputs N, S, W, E .

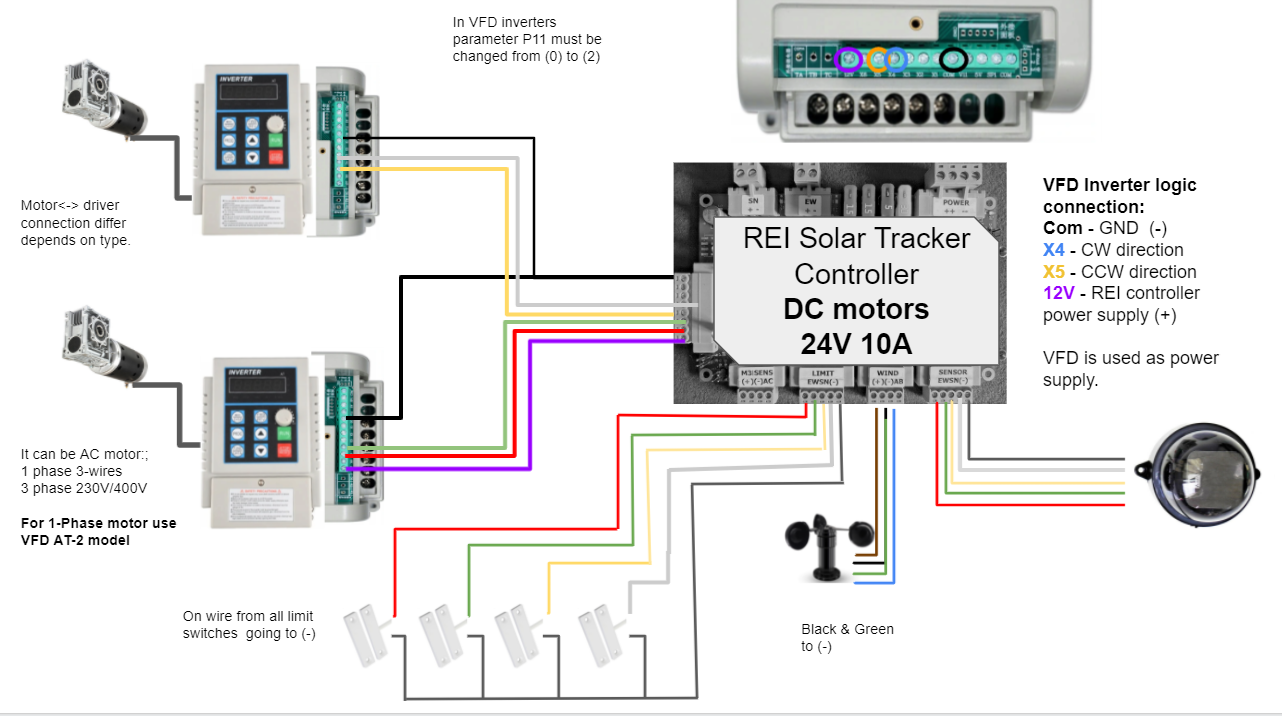

REI Solar Tracker Controller have implemented logical limit switches noise-resistant and lets You manage construction in safe way. In that way You can really stop supply power to motors. You can also control any type of motors by external drives. Even more. You can control DC and BLDC/stepper or AC motor at the same time. Imagine some construction where in one function You are using linear actuator and to other direction You need AC 3 phase motor. Rei Controller lets You do that. See example schema bellow.

The optical driver is configurable with six buttons. To control the tracker manually press the "M" button for 1s To enter the configuration menu, press the "M" button for 5 seconds. To return to the automatic operation of the system (save the settings) press the "C" button.